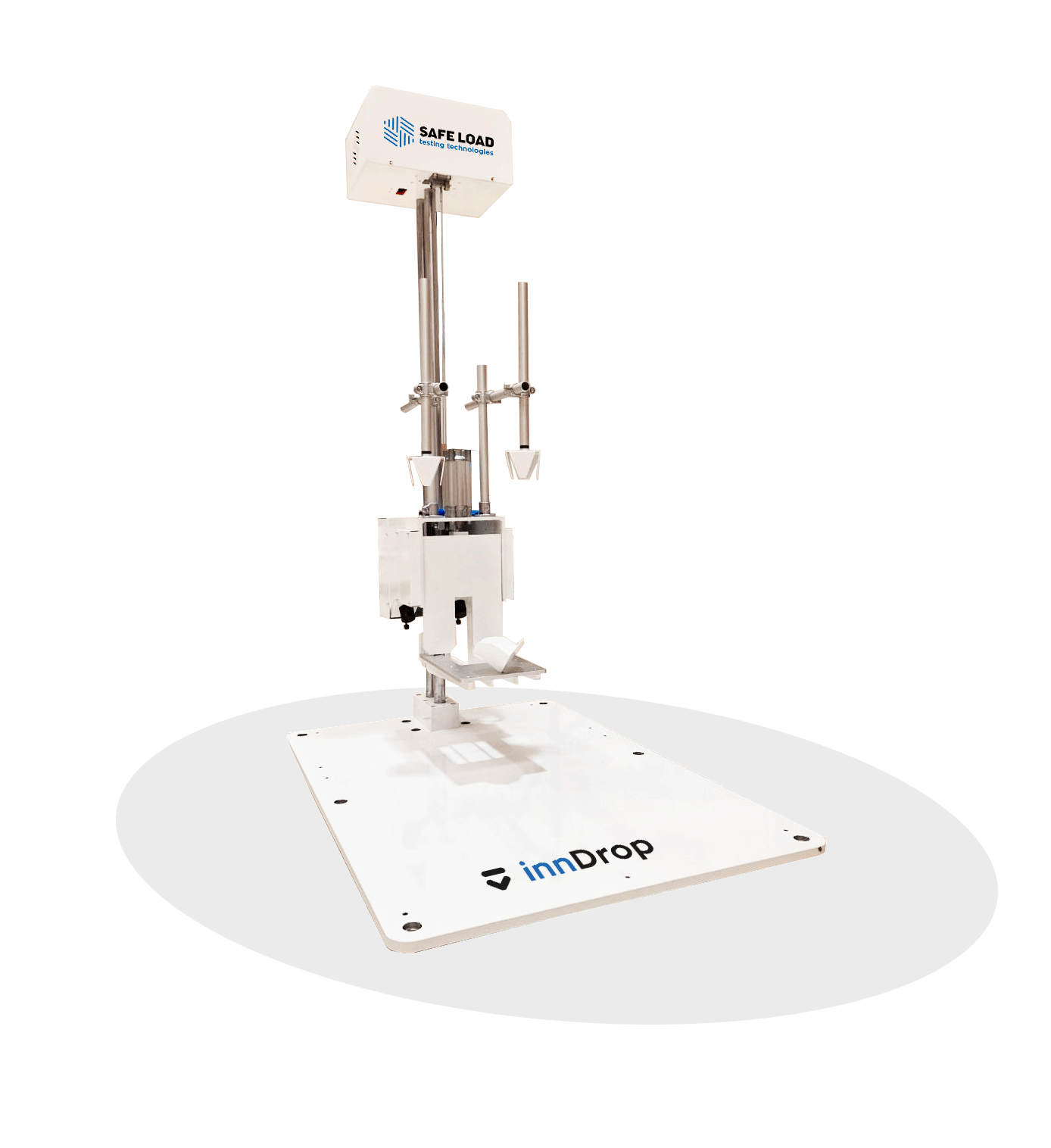

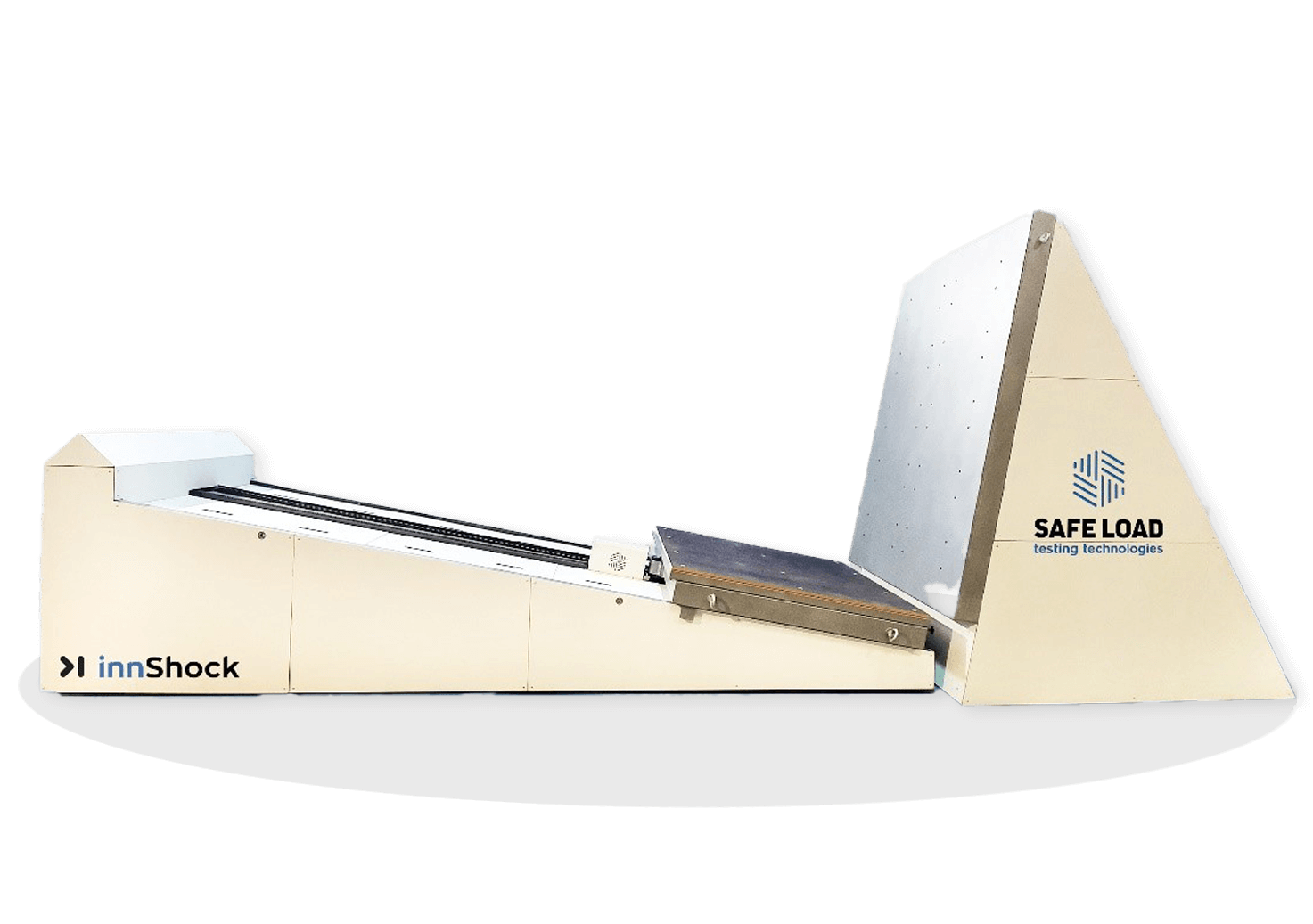

The innDrop series evaluates the ability of packages to withstand free-fall impacts during handling and shipping. With models adapted to different weight classes, they simulate flat, edge, and corner drops in compliance with ISTA, ASTM, ISO, EN 15552 and MIL-STD standards. These testers help manufacturers minimize product damage and optimize packaging performance.

(≤100 kg) Ideal for lighter packages, this compact tester reproduces common drop scenarios with accuracy, ensuring protection of consumer goods and retail packaging.

(>100 kg) Built for bulkier and industrial packaging, this heavy-duty tester validates protection levels for large products, reducing costly transport-related losses.

.png)